Research on safety risk assessment of polyimide foam production line based on AHP-FCE method

Downloads

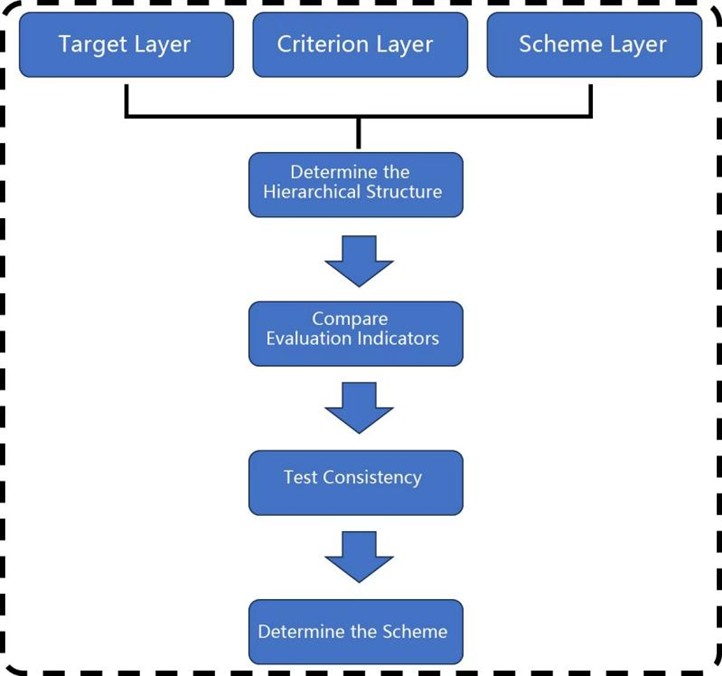

Polyimide foam, as a high-performance sandwich composite material, is widely used in high-tech manufacturing industries such as aviation and aerospace. Nevertheless, its production process involves numerous hazardous chemicals and sophisticated machinery, which is extremely hazardous to the system itself. Today, the overall assessment tools for multidimensional safety risks on the production line are unsatisfactory. To address this, this paper developed a safety risk assessment system comprising five dimensions: equipment, materials, personnel, environment, and management. The study applied the Analytic Hierarchy Process (AHP) to calculate indicator weights and the Fuzzy Comprehensive Evaluation Method (FCE) to assess safety risk in a polyimide foam line. The results show that the overall risk level of this production line is Relatively High, and the main sources of risk are equipment factors and process-material factors. Simultaneously, personnel and safety management factors should also be considered. Based on the evaluation findings, specific risk control measures are offered, with both theoretical background and methodological underpinning for the safety design and operational management of polyimide foam production lines.

Wu Haitao, Liu Tiantian, Pan Li, et al. Research and Application of Polyimide Foam. Chemical New Materials, 2023,51(10):231–234,238.

Li Renhao, Bao Yan, Zhao Haihang. Research Progress on Polyimide-based Composite Thermal Insulation Materials. Materials Herald, 2025,39(10):231–240.

Zhang Litong, Sun Liqiang, Zhang Ruihan, et al. Preparation and Thermal Properties of Polyimide Foam. Functional Materials, 2025,56(2):2179–2185.

Yabin, Ding Zhaojun, Pei Leizhen, et al. Performance and microstructure of polyimide-modified high-strength composite foam materials. Plastic Technology, 2025,53(9):1–7.

Zhang Yudi, Yu Hao, Xu Xinyu. Research Progress on Inorganic Material-Modified Polyimide Composites. Synthetic Resin and Plastics, 2021,38(3):71–76.

Yang Fukai, Zhang Yudi, Deng Yuyuan, et al. An Overview of the Performance of Polyimide Foam Materials. China Plastics, 2020,34(11):94–101.

Jia Jialin, Sun Yunlong, Zhou Huafeng, et al. Preparation of polyimide foam via powder method and its properties. Chemical New Materials, 2025,53(3):88–91.

Cheng Chuyun. Preparation, Properties, and Foam Applications of High-Strength and High-Toughness Polyimide Nanofiber Yarns. Jiangxi Normal University. https://doi.org/10.27178/d.cnki.gjxsu.2025.000002.

He Lihua, Li Huixia, Liu Zhiling, et al. Preparation and Properties of Polyimide-Modified Melamine Foam. Engineering Plastics Applications, 2025,53(4):8–14.

Xu Yang, Wang Yandong, Xu Haocheng, et al. Design and Properties of High-Restoration Silicone-Modified Polyimide Foam Materials . Aerospace Materials Technology, 2024,54(6):59–64.

Xie J, Liu B, He L, et al. Quantitative Evaluation of the Adaptability of the Shield Machine Based on the Analytic Hierarchy Process (AHP) and Fuzzy Analytic Hierarchy Process (FAHP). CHEN Q.Advances in Civil Engineering, 2022, 2022(1): 3268150.

Cheng EWL, Li H, Ho DCK. Analytic hierarchy process (AHP): A defective tool when used improperly. Measuring Business Excellence, 2002, 6(4): 33–37.

Li Jinkun. Research on Improving Risk Management in R&D Projects at A Technology Company. Jilin University, 2025. https://doi.org/10.27162/d.cnki.

gjlin.2025.006163

Lim H, Kim S, Kim Y, et al. Relative Importance Analysis of Safety Climate Evaluation Factors Using Analytical Hierarchical Process (AHP). Sustainability, 2021, 13(8): 4212.

Huo Lingjie. Research on the Collaborative Mechanism of Regional Engineering Education under the Belt and Road Initiative in the Perspective of Global Governance. Value Engineering, 2025,44(29):67–70.

Fan Chuntan, Yue Jianping, Feng Yong, et al. Research on Green Construction Methods for Urban Underground Utility Tunnels Using Fuzzy Comprehensive Evaluation Methodology. Railway Standard Design, 2025.

Sun Guochao, Gu Xiaofeng, Chen Jianye, et al. A HBP-Fuzzy Comprehensive Evaluation Model for Beautiful Rural Roads and Its Application. Journal of Highway, 2024,69(11):245–255.

Liu Chengxing, Feng Fenqiang. Construction of an Evaluation Index System for Equipment Supply Chain Security Risks. Military Operations Research and Evaluation, 2025,40(1):49–52.

Abrahamsen EB, Abrahamsen HB, Milazzo MF, et al. Using the ALARP principle for safety management in the energy production sector of chemical industry. Reliability Engineering & System Safety, 2018, 169: 160–165.

Lv C, Wang X, Xue S, et al. Investigation of risk-aware dynamic accident monitoring and early warning technologies for chemical production processes. Scientific Reports, 2025, 15(1): 9466.

Li Jinliang. Discussion on Chemical Safety and Emergency Management. China Petroleum and Chemical Standards and Quality, 2025,45(16):61–63.

Li Tingbo. Development and Application of Chemical Safety Production Risk Assessment System. Chemical Management, 2024, (28):98–101.