Sustainable lathe machine selection using PROMETHEE

Downloads

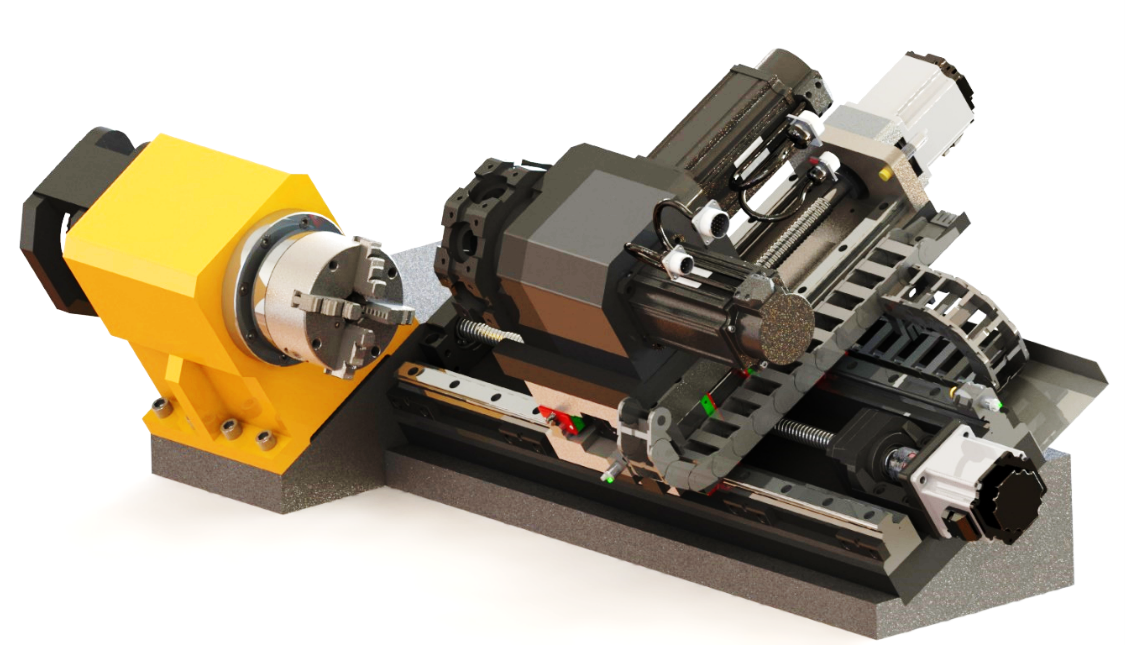

The manufacturing echelon of supply chains utilizes several machines to convert raw materials into finished products. Therefore, during procurement of these machines, supply chain managers are usually saddled with the problem of obtaining the best machine from a group of similar alternatives, considering multiple criteria simultaneously. The main purpose of this study is to utilize the Preference Ranking Organization Method for Enrichment Evaluation (PROMETHEE) for selecting the best lathe machine from a group of five (5) similar alternatives, namely Lathe 1, Lathe 2, Lathe 3, Lathe 4 and Lathe 5. Four (4) criteria were used in evaluating the machines, namely power, price, complexity, and weight, with preference weights of 0.25, 0.3, 0.25, and 0.2, respectively. The results indicated that Lathe 2 is the best alternative because it has the highest total net flows of 0.325, followed by Lathe 5, which has total net flows of 0.03. Next is Lathe 1, which has a total net flow of -0.0188, followed by Lathe 3, having a total net flow of -0.0975, and finally, Lathe 4, which is the worst ranking alternative, having a total net flow of -0.2388. Therefore, PROMETHEE proved to be a viable multi-criteria decision-making tool for selecting the most suitable lathe machine among the group of alternative machines. This study is significant because it provides a procedure for aiding supply chain managers in selecting the best alternative among a group of similar alternatives using PROMETHEE.

Zekhnini K, Cherrafi A, Bouhaddou I, Benghabrit Y, Garza-Reyes JA. Supply chain management 4.0: a literature review and research framework. Benchmarking: An International Journal, 2021. 28(2): 465-501.

Wofuru-Nyenke OK. Critical path method utilization for optimal scheduling of production activities. Future Sustainability, 2024. 2(3): 1-5.

Wofuru-Nyenke OK, Nkoi B, Oparadike FE. Waste and Cost Reduction for a Water Bottling Process Using Lean Six Sigma. European Journal of Engineering and Technology Research, 2019. 4(12): 71-77.

Dora M, Biswas S, Choudhary S, Nayak R, Irani Z. A system-wide interdisciplinary conceptual framework for food loss and waste mitigation strategies in the supply chain. Industrial Marketing Management, 2021. 93: 492-508.

Nyenke OKW. Value stream mapping: A tool for waste reduction. International Journal of Innovative Research and Development, 2021. 10(6): 13 - 20.

Wofuru-Nyenke O, Briggs T. Predicting demand in a bottled water supply chain using classical time series forecasting models. Journal of Future Sustainability, 2022. 2(2): 65-80.

Wofuru-Nyenke OK. Forecasting Model Accuracy Assessment in a Bottled Water Supply Chain. International Journal of Engineering and Modern Technology, 2022. 8(5): 101-108.

Wofuru-Nyenke OK, Briggs TA, Aikhuele DO. Advancements in sustainable manufacturing supply chain modelling: a review. Process Integration and Optimization for Sustainability, 2023. 7(1): 3-27.

Rizzo A, Goel S, Luisa Grilli M, Iglesias R, Jaworska L, Lapkovskis V, Novak P, Postolnyi BO, Valerini D. The critical raw materials in cutting tools for machining applications: A review. Materials, 2020. 13(6): 1377.

Wofuru-Nyenke OK. Leading-edge production engineering technologies. Journal of Newviews in Engineering and Technology (JNET), 2021. 3(4): 9-17.

Rinaldi M, Caterino M, Fera M, Manco P, Macchiaroli R. Technology selection in green supply chains-the effects of additive and traditional manufacturing. Journal of Cleaner Production, 2021. 282: 124554.

Wofuru-Nyenke OK. Mechanized cover crop farming: Modern methods, equipment and technologies. Circular Agricultural Systems, 2023. 3(1).

Wofuru-Nyenke OK. Carbon Emissions Modeling for Smarter Carbon Footprint Decisions: A Systematic Review. BOHR International Journal of Civil Engineering and Environmental Science (BIJCEES), 2023. 1(2): 75 - 87.

Wofuru-Nyenke O. Biodegradable Cutting Fluids Evaluation for Sustainable Machining Processes. Universal Journal of Green Chemistry, 2024: 117-124.

Ugoji KU, Isaac OE, Nkoi B, Wofuru-Nyenke O. Improving the Operational Output of Marine Vessel Main Engine System through Cost Reduction using Reliability. International Journal of Engineering and Modern Technology (IJEMT), 2022. 8(2): 36-52.

Wofuru-Nyenke O. Routing and facility location optimization in a dairy products supply chain. Future Technology, 2024. 3(2): 44-49.

Anand G, Kodali R. Selection of lean manufacturing systems using the PROMETHEE. Journal of modelling in management, 2008. 3(1): 40-70.

Araz OU. A simulation based multi-criteria scheduling approach of dual-resource constrained manufacturing systems with neural networks. In Australasian Joint Conference on Artificial Intelligence. 2005. Springer.

Belz R, Mertens P. Combining knowledge-based systems and simulation to solve rescheduling problems. Decision Support Systems, 1996. 17(2): 141-157.

Duvivier D, Roux O, Dhaevers V, Meskens N, Artiba A. Multicriteria optimisation and simulation: an industrial application. Annals of Operations Research, 2007. 156: 45-60.

Roux O, Duvivier D, Dhaevers V, Meskens N, Artiba A. Multicriteria approach to rank scheduling strategies. International Journal of Production Economics, 2008. 112(1): 192-201.

Cavalcante C, De Almeida A. A multi‐criteria decision‐aiding model using PROMETHEE III for preventive maintenance planning under uncertain conditions. Journal of Quality in Maintenance Engineering, 2007. 13(4): 385-397.

Chareonsuk C, Nagarur N, Tabucanon MT. A multicriteria approach to the selection of preventive maintenance intervals. International Journal of Production Economics, 1997. 49(1): 55-64.

Parreiras RO, Maciel JH, Vasconcelos JA. The a posteriori decision in multiobjective optimization problems with smarts, promethee II, and a fuzzy algorithm. IEEE Transactions on Magnetics, 2006. 42(4): 1139-1142.

Rekiek B, De Lit P, Pellichero F, L'Eglise T, Fouda P, Falkenauer E, Delchambre A. A multiple objective grouping genetic algorithm for assembly line design. Journal of intelligent manufacturing, 2001. 12: 467-485.

Rekiek B, De Lit P, Delchambre A. Hybrid assembly line design and user's preferences. International Journal of Production Research, 2002. 40(5): 1095-1111.

Waeyenbergh G, Vannieuwenhuyse B, Pintelon L. A model to determine the cleanliness measurement interval in an automotive paint shop. Journal of Quality in Maintenance Engineering, 2004. 10(1): 37-46.

Mastos TD, Nizamis A, Vafeiadis T, Alexopoulos N, Ntinas C, Gkortzis D, Papadopoulos A, Ioannidis D, Tzovaras D. Industry 4.0 sustainable supply chains: An application of an IoT enabled scrap metal management solution. Journal of cleaner production, 2020. 269: 122377.

Wofuru-Nyenke OK. Design Analysis of a Portable Manual Tyre Changer. European Journal of Engineering and Technology Research, 2020. 5(11): 1307-1318.

Wofuru-Nyenke O. Reliability assessment and accelerated life testing in a metalworking plant. Future Technology, 2024. 3(3): 1-7.

Brans J, Vincke P. Preference Ranking Organization Method-(the Promethee Method forMultiple Criteria Decision-Making). Management Science, 1985. 31: 647-656.

Brans J, Mareschal B, Figueira J, Greco S. Multiple criteria decision analysis: state of the art surveys. New York, USA: Springer Science+ Business Media, Inc, 2005: 163-196.

Ishizaka A, Nemery P. Multi-criteria decision analysis: methods and software. 2013: John Wiley & Sons. DOI:10.1002/9781118644898